Get a Quote

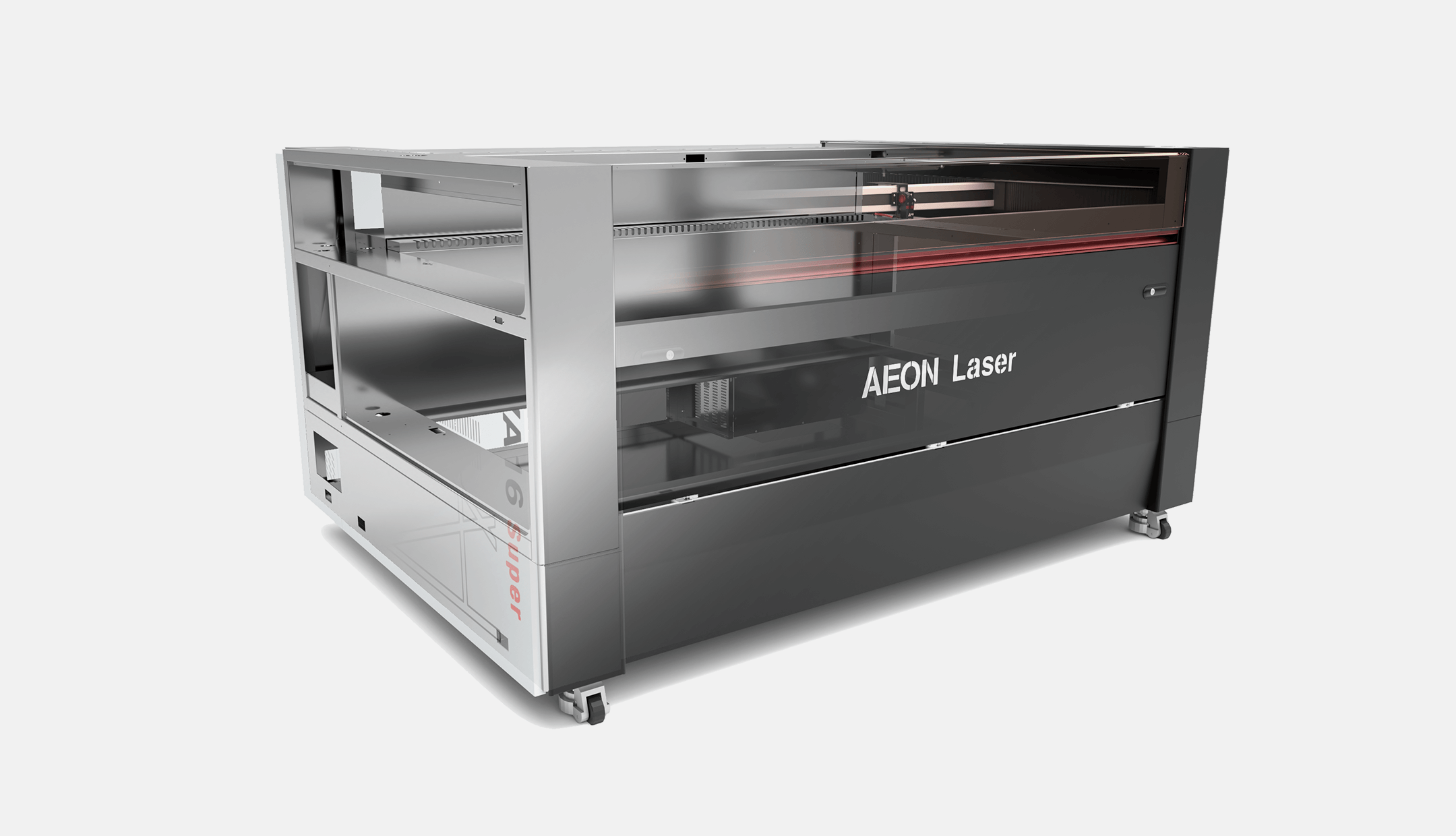

Redline NOVA Super

Unrivaled Speed Exceptional Precision

Fueling Your Efficiency

Fueling Your Efficiency

Why Redline Super NOVA can reach 4200mm/s with 8G acceleration

speed while keeping an phenomenal precision?

speed while keeping an phenomenal precision?

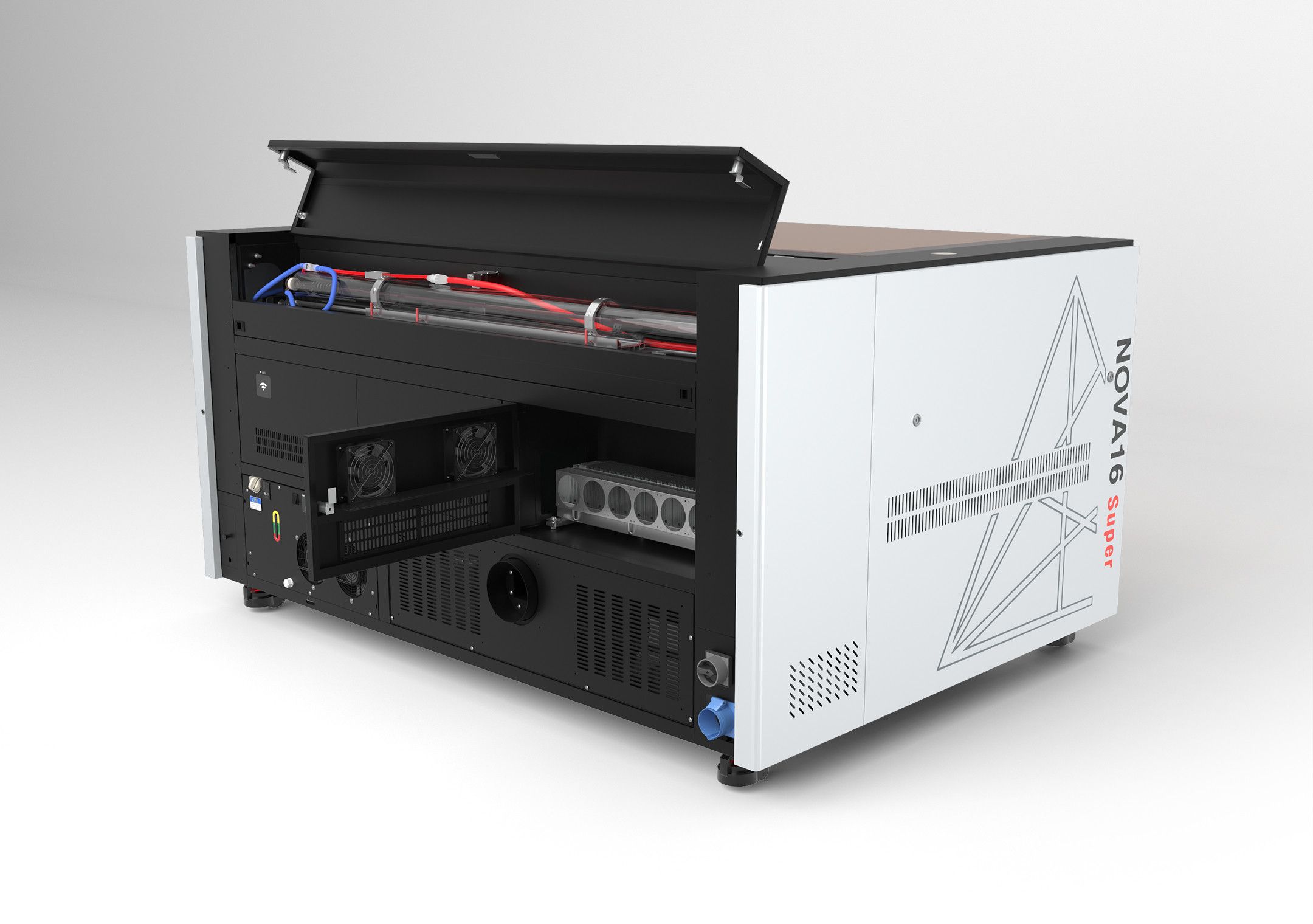

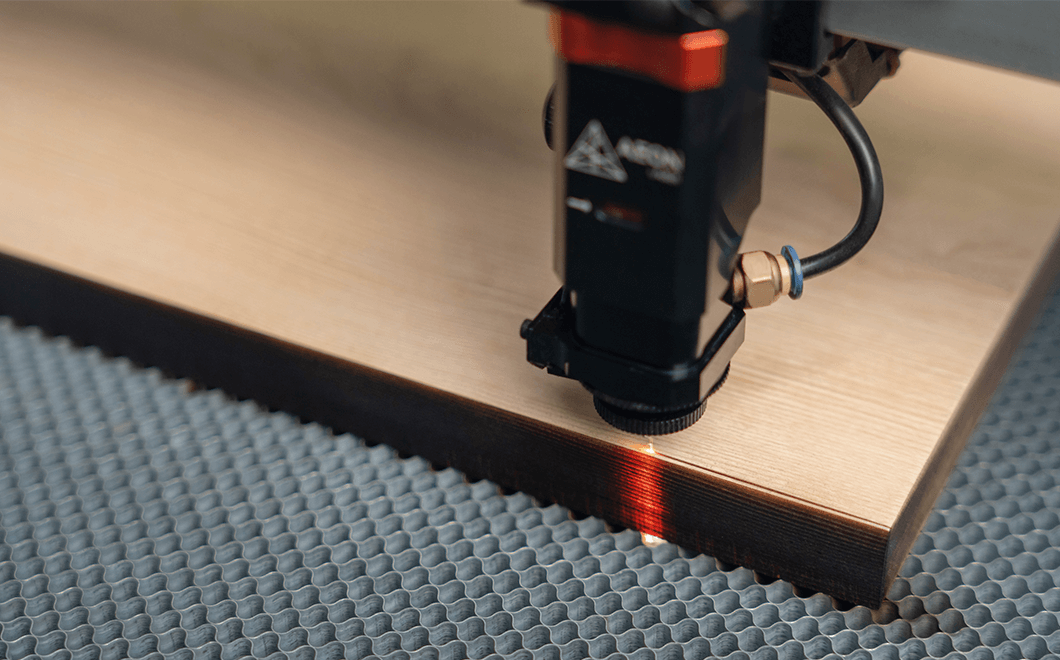

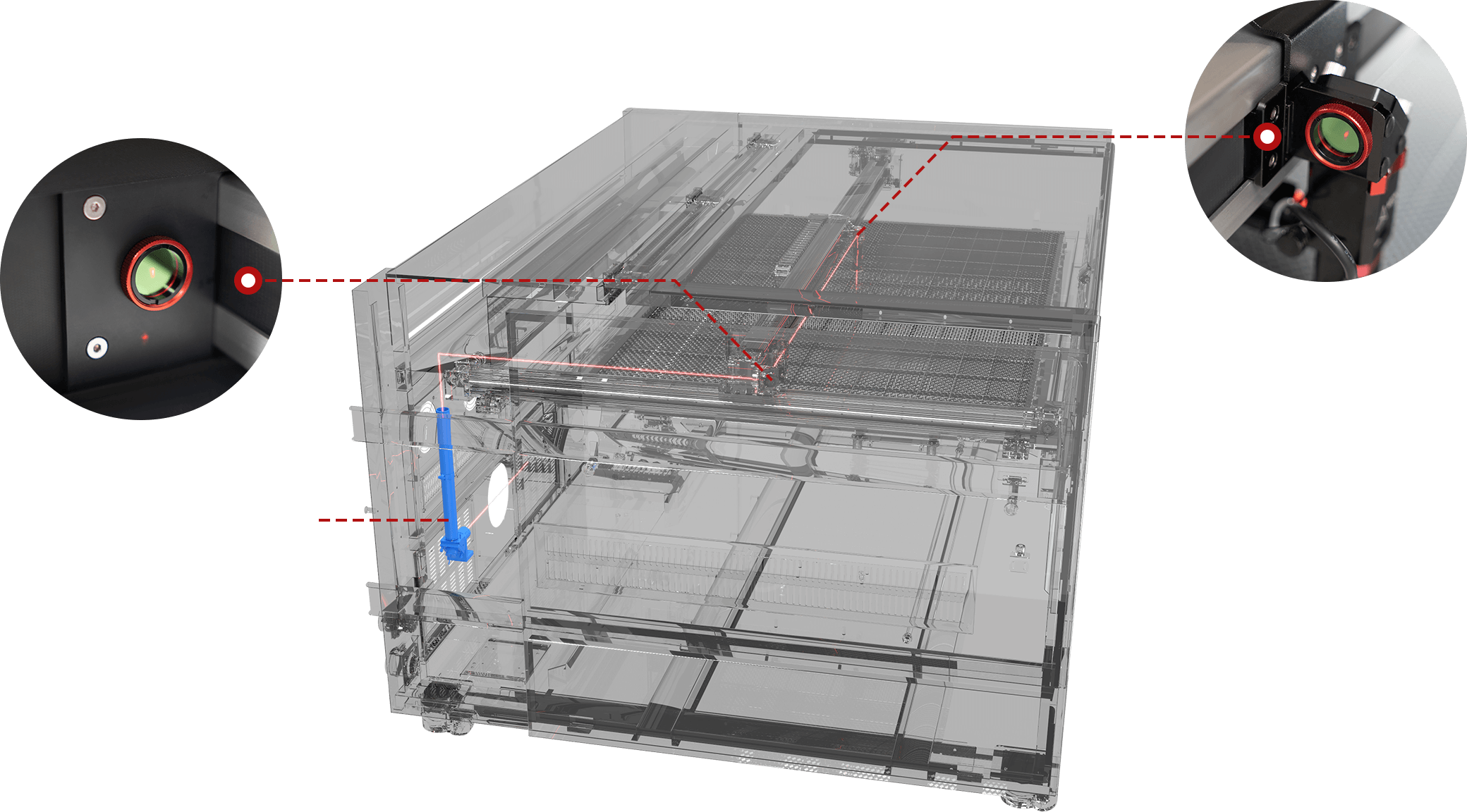

Dual Laser Source

The Redline NOVA Super got a Metal RF tube and a high power DC glass tube inside. For high resolution and high speed engraving, the RF tube is a must. For thicker material cutting, a high power glass tube got its advantage. Users can switch from engraving and cutting seamlessly. Perfectly combined the high precision engraving and high power cutting in one machine.

Fastest Engraving Speed

4200mm/sec

For high resolution and high speed engraving,

the RF tube is a must.

the RF tube is a must.

Infinite Possible Cutting Thickness

Max…

For thicker material cutting,

a high power glass tube got its advantage.

a high power glass tube got its advantage.

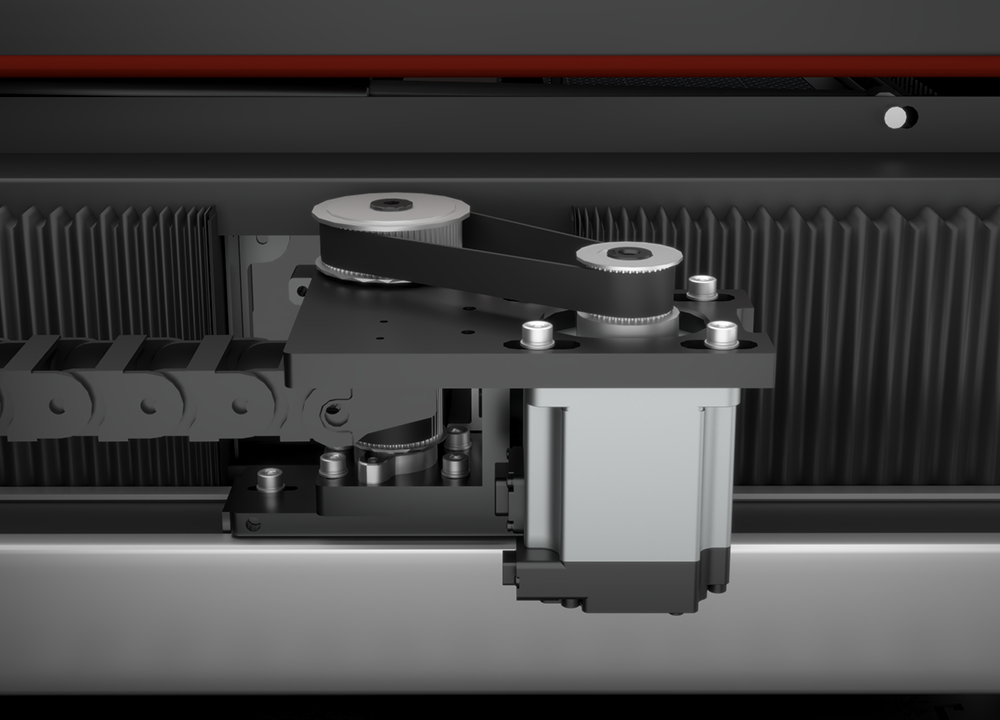

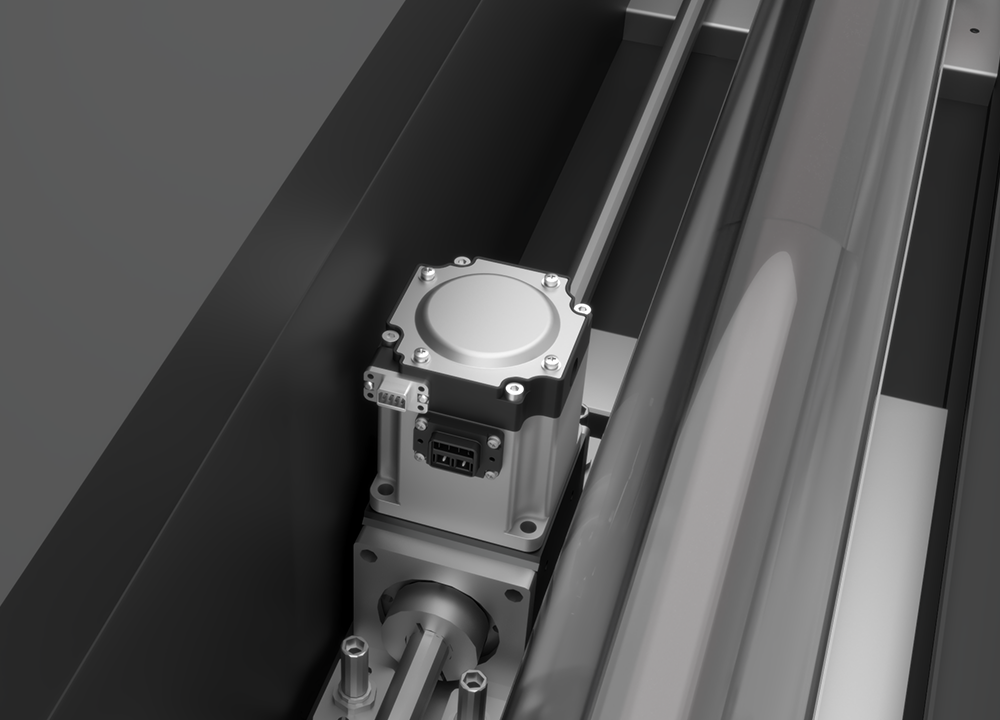

Full AC Servo Motor

No more hybrid servo, step into the real close-loop era with AEON Laser.Full AC Servo Motors make acceleration nearly instant at 8G of force with top speeds of 4,200 mm/sec on RF models. Of course, the motor alone is not the whole recipe. Some manufacturers may use similar motors, but achieving comparable speed and precision with longevity remains a unique feat of AEON Laser.

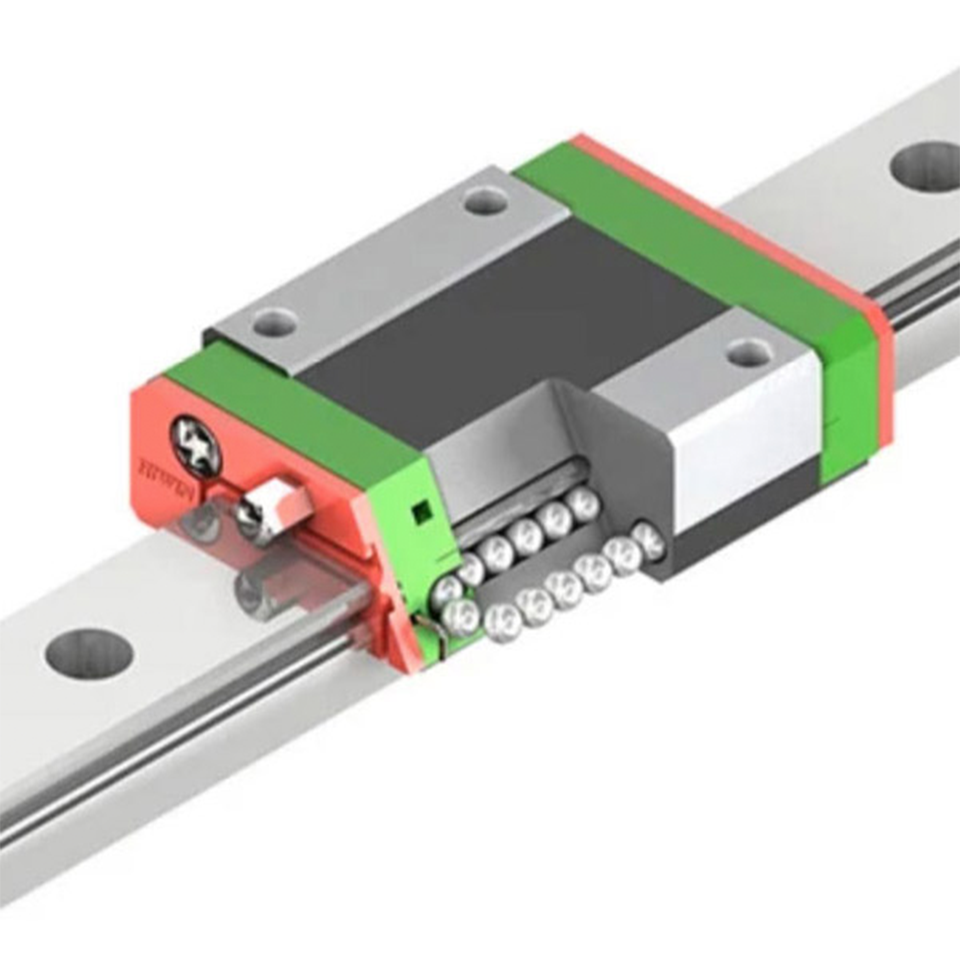

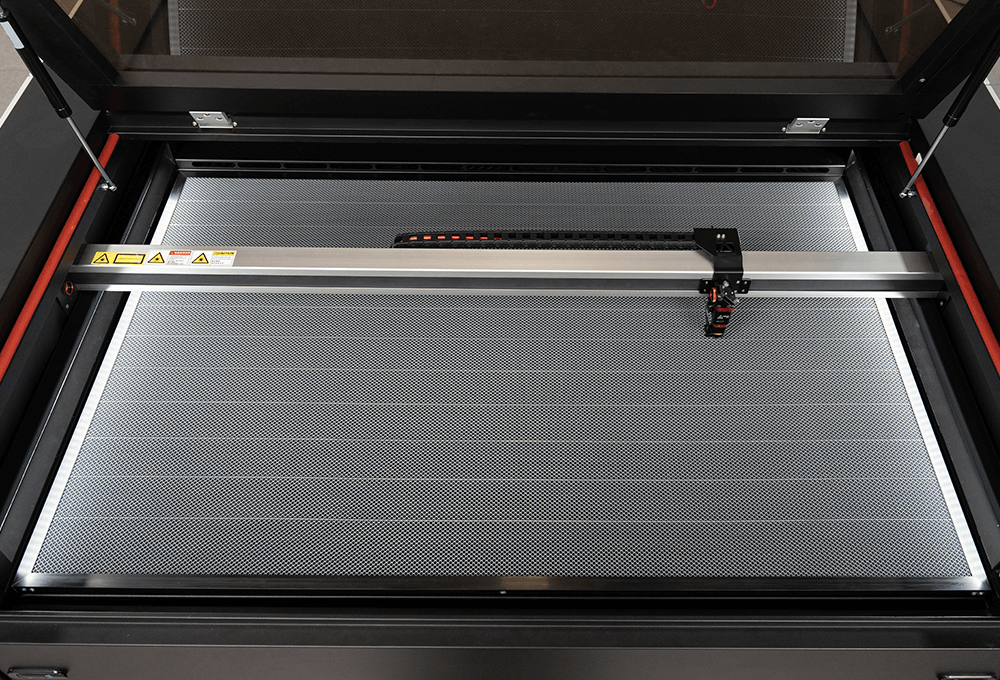

Rigid Linear Guide Rail

Linear guide rails with ball bearings offer greater precision and smoother motion, which improves print quality and longevity. Further, AEON Laser has been conducting rigorous test on all kinds of rails for over 7 years, and selected the most rigid one to meet the requirements for high speed and high precision.

Robust Unibody

Most lasers employ a unibody structure where the components are bolted to a thin outer shell. However, if you have the need for speed, it's of utmost importance to make the frame as rigid as possible to stop the machine from flexing. The Redline series frame is super robust, featuring thick steel tubes that reinforce the structure. It is designed to withstand at least 10G of force. By the way, the Redline NOVA remains easily separable, allowing it to pass through narrow doors and doorways.

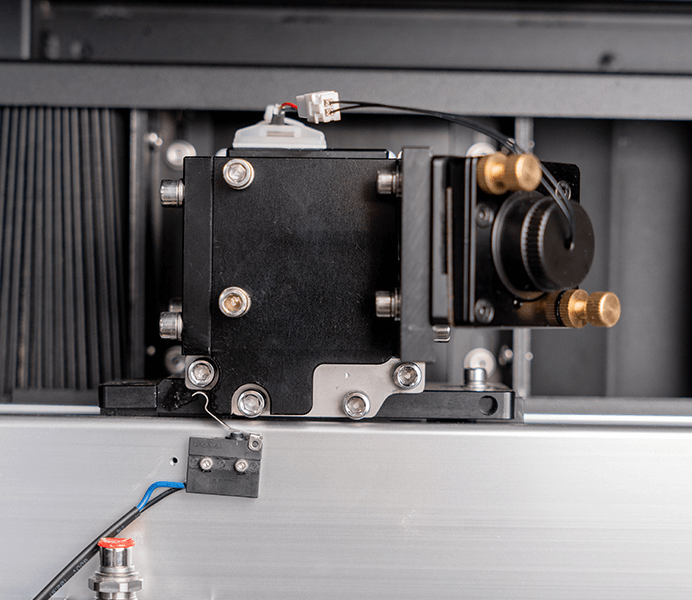

Feather weight laser head

A lightweight laser head contributes to less over-scanning and an overall reduction in vibration, reducing motor load and significantly enhancing the speed.

Get a Quote

Effortlessly Serviceable

Minimizing Maintenance Downtime To The Utmost

Minimizing Maintenance Downtime To The Utmost

The first and foremost goal is to minimize the maintenance cycle,

if we must do it, AEON made sure you do it in easiest way with its distinctive features.

if we must do it, AEON made sure you do it in easiest way with its distinctive features.

Tool-less Optic Path

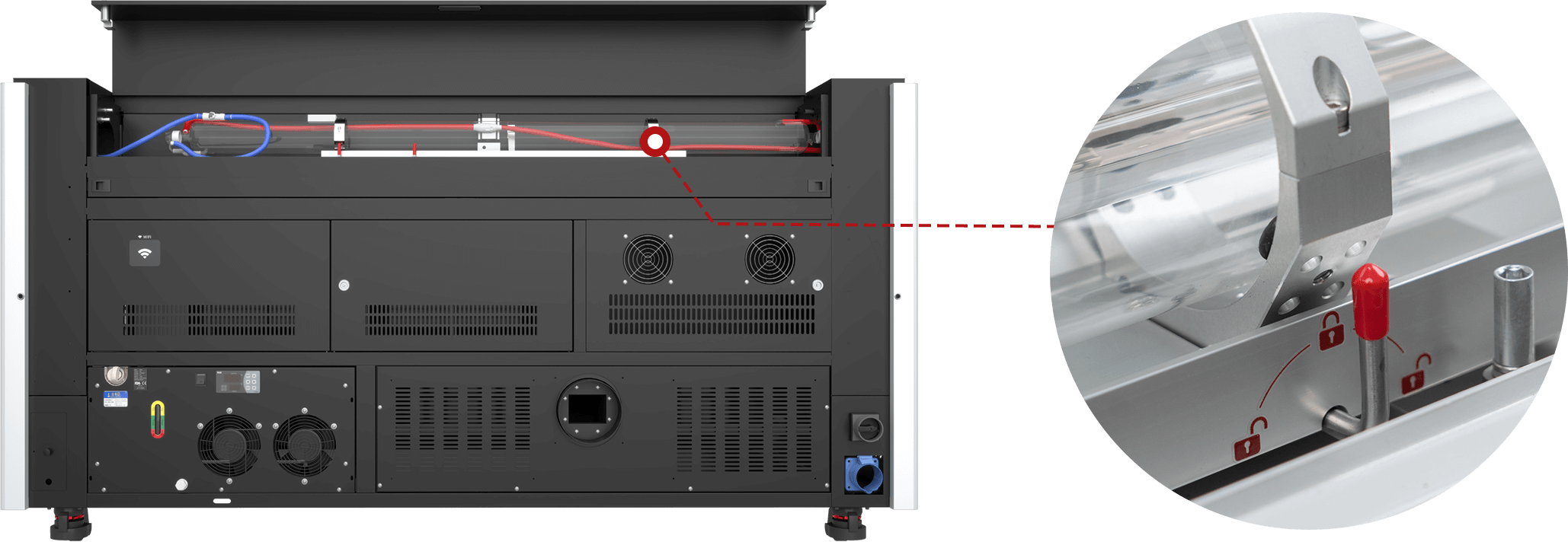

Laser Tube Docking Station

Say goodbye to painstaking tube replacements and aligning the laser path. This innovative approach allows for swapping of tubes in and out of your Aeon laser, without having to renegotiate the beam path.

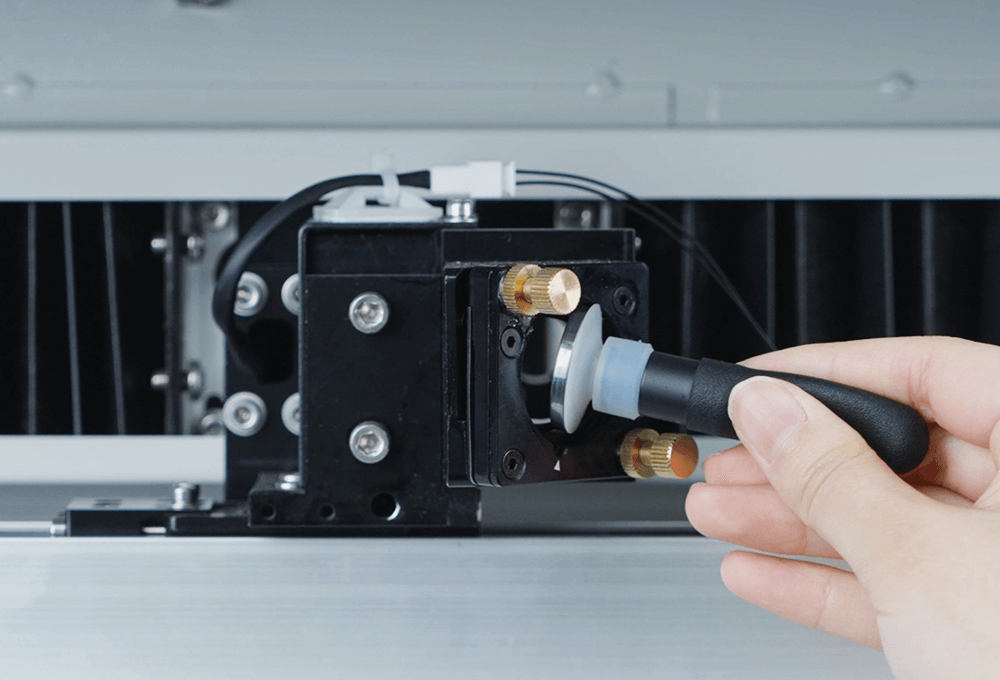

Mirror

All mirrors are now easily accessible and can be cleaned or replaced without the use of any tools or having to re-calibrate.

Lens Carriage

The lens cartridges on all Redline models are now magnetic and the focal lens itself is press fit with a silicone washer. Users can easily clean or swap lenses for different tasks.

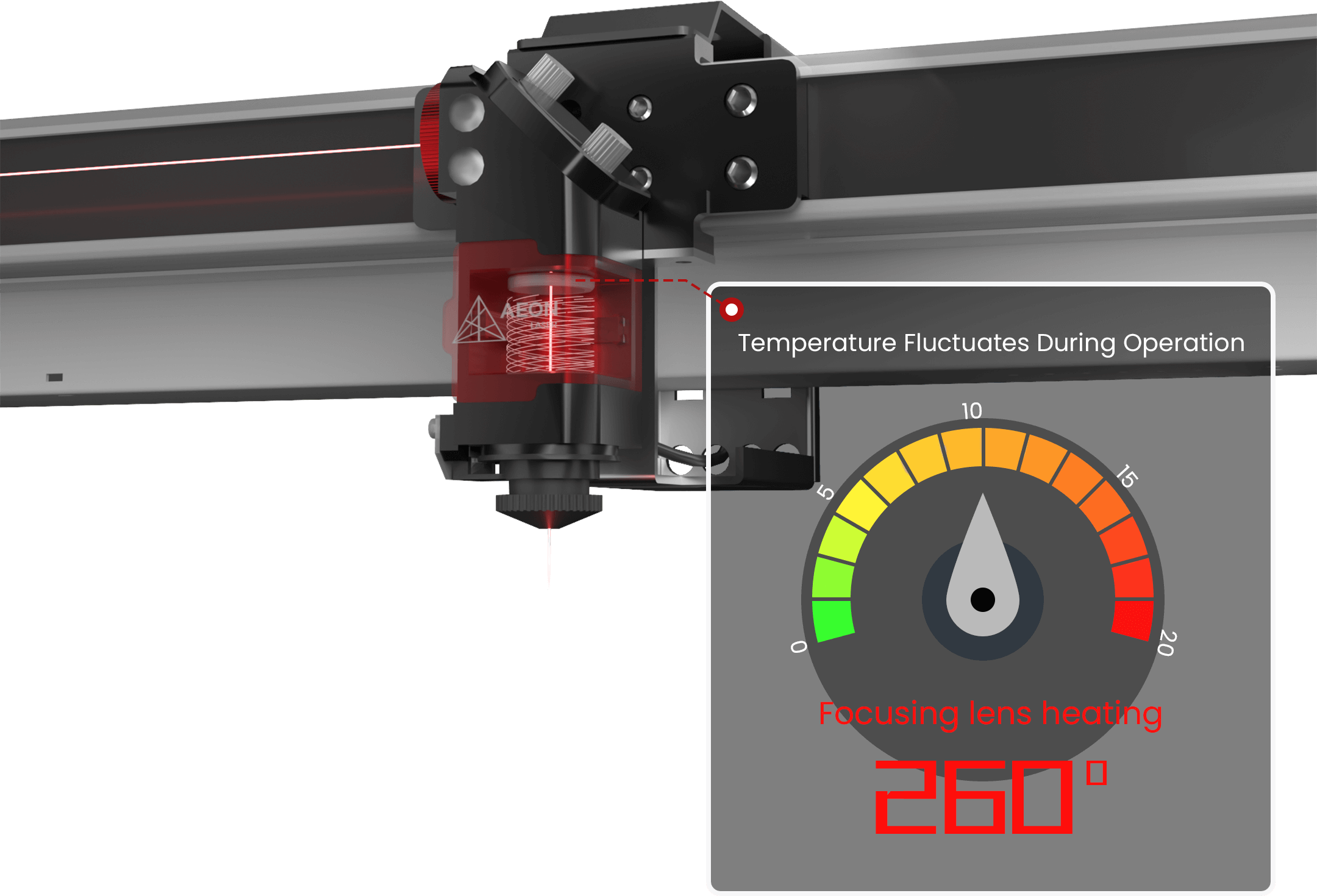

Pro-smart Monitoring & Alert System

All optics are now fitted with thermal sensors to record and report temperature readings to the keypad, thus eliminating the likelihood of unexpected failures, and should the temperature rise too high, an alert prompts immediate cleaning of mirrors or lenses.

Additionally, the system will remind you to do some essential maintenance, such as greasing the guide rail, drain water of the built-in compressor for Redline NOVA. Yes, you are not mistaken, the Redline NOVA had a ultra quiet compressor inside which can be maintained with one touch.These proactive approach not only saves you from costly mistakes and downtime, it also reduces the need for frequent unwarranted cleaning. To top it off, the controller now records these readings along with ambient temperature, laser tube runtime and machine parameters, to serve as a diagnostic log in the event troubleshooting is needed.

Modular Design

The idea of designing an easily serviceable machine is deeply rooted in AEON's philosophy. Most parts that are designed for rapid removal and replacement, utilizing quick connectors for ease of use. From chillers to sensors and motors, any issues can be swiftly addressed by simply submitting a ticket. Our service team will promptly deliver the necessary parts, enabling even novices to perform replacements without any trouble.

Engineered for endurance

steadfast reliability for perpetual performance

steadfast reliability for perpetual performance

Not to mention the robust structure of the cabinet, rigid linear guide rail, premium AC servo motor...

We go the extra mile to ensure our machine's enduring performance, free of issues.

We go the extra mile to ensure our machine's enduring performance, free of issues.

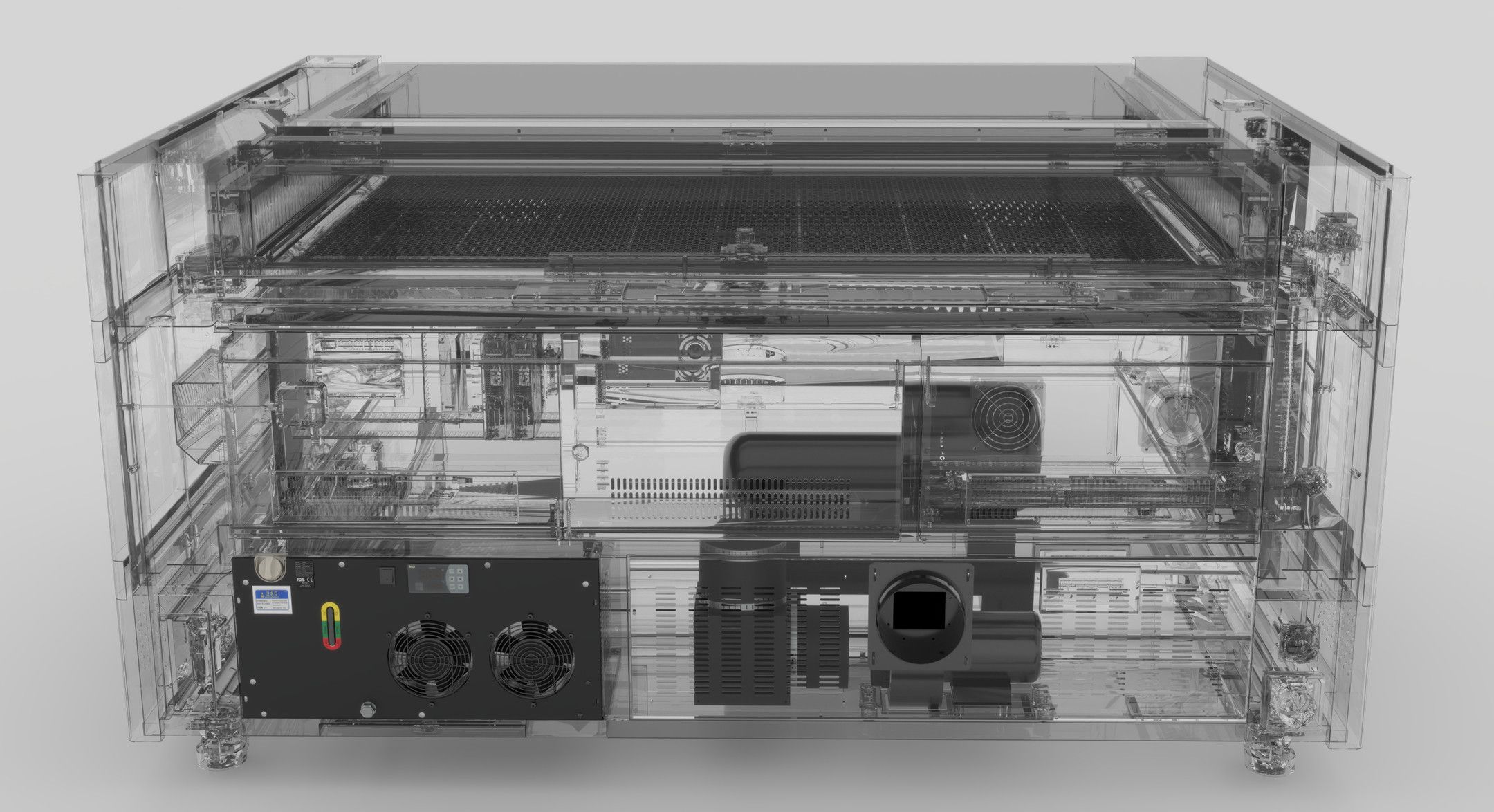

Super Clean Pack Design

Not only are the linear rails and bearing blocks enclosed, but protective curtains on the left and right side rails now prevent unwanted parti cles from spreading beyond your work area. This can significantly prolongs rail lifespan and greatly enhances cutting and engraving quality.

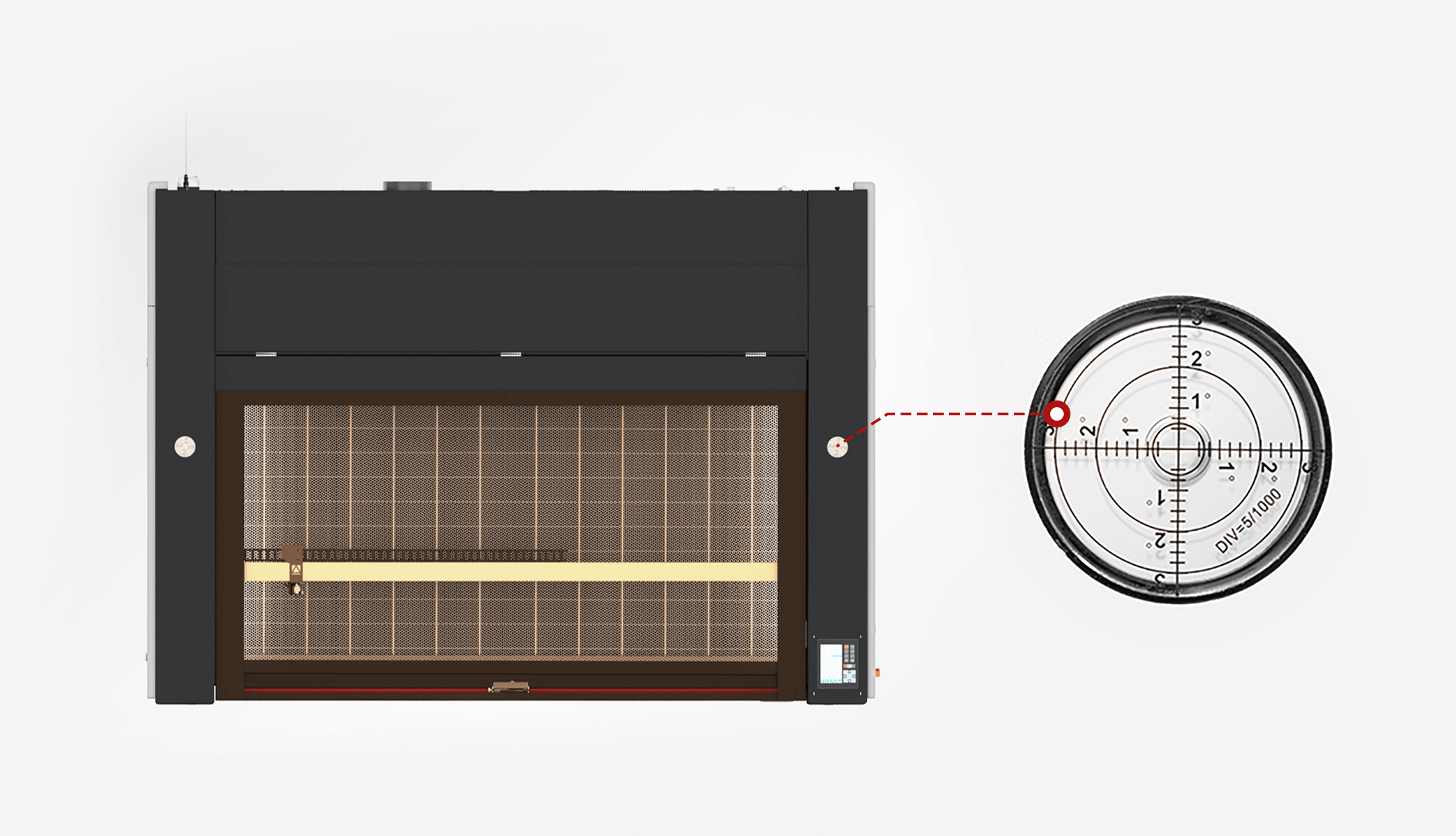

Bullseye Leveling Gauge

Each Redline series machine has a bullseye leveling gauge, ensuring your laser is level can now be done at a glance-a critical detail often missed by engineers. Proper leveling is essential, without it, axles suffer increased friction and distortion, remarkably shortening rail lifespan.

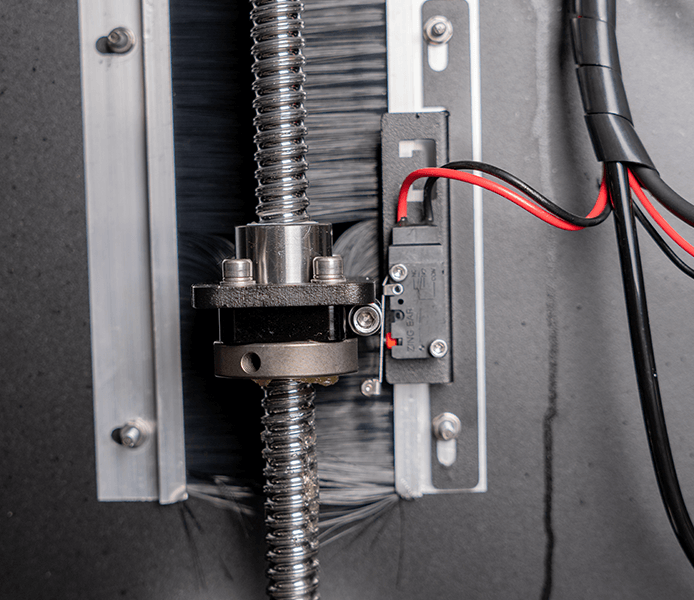

Mechanical Micro Switch

The AEON engineer team introduced mechanical micro switch in Redline series to replace the photoelectric limit sensor . These micro switches are very reliable,built for over 200,000 cycles of flawless operation.

Securely Sealed Optical Path

AEON's engineers are using every possible method to combat dust and extend the lifespan of optical parts. We enclosed the laser path with aluminum tubes and added protective lenses for the mirrors. This will considerably reduce the maintenance frequency and extend the life span of your laser tubes, mirrors and lenses.

aluminum tubes

Own it and start your creative journey...

Get a Quote

Intuitive User-friendly

Ensuring Smooth Operation & A Short Learning Curve

Ensuring Smooth Operation & A Short Learning Curve

Whether you're upgrading from a hobby laser or you are a completely new bee,

our streamlined workflow ensures you get up and running seamlessly

our streamlined workflow ensures you get up and running seamlessly

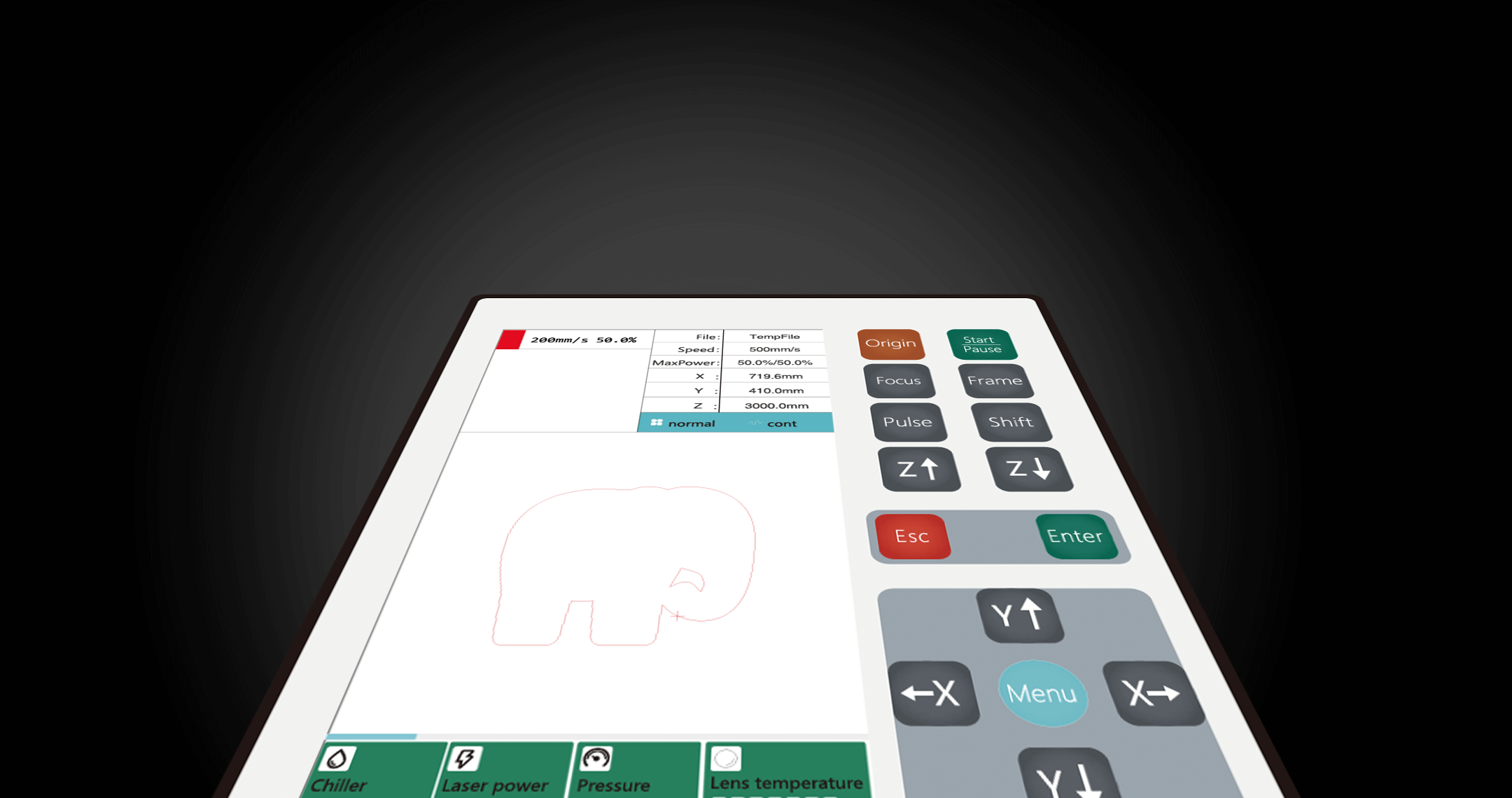

Large LCD Screen

The Redline series is enhanced with large LCD screen that worked with the latest firmware. The combo key put the Common functions at your fingertips,reducing setup times and simplifying use.You can monitor water temperature, amperage (mA), air pressure (psi), and the temperature of your optics right from the vibrant 5" LCD display, providing the ultimate user experience.

Larger…

Easier…

One Touch

Integrated Autofocus

Integrated Autofocus

Wave goodbye to collisions and gouged material. The Redline Series has a newly designed laser head with integrated autofocus. With just one touch, the laser will focus itself automatically.

High Resolution Camera

All Redline models are now equipped with built-in high-resolution cameras for precise positioning and monitoring. It’s new bee’s welfare to have this fantastic visual operation.

Material Pass-through Door

In the Redline Series, our design team has finally been able to include an infinite front-to-back pass-through in all MIRA models! Make it possible to process longer material in a desktop grade machine.

Automated Exhaust

Stay calm when you can't find the switch for the exhaust fan. It now runs automatically with the job. You could set up to 5 minutes delay time in software. This helps reduce your electric bill and allows you to enjoy peace of mind when the machine is idle.Another dark technology we introduced in Redline NOVA is that, it can switch automatically based on the task. During cutting, it closes the upper extraction airway to prevent laser reflection and material charring. For engraving, it closes the bottom extraction for a cleaner result.

Wireless Connection

The new WiFi enables users to connect machine wirelessly while surfing the internet, eliminating messy data cables. It also paved the way to operate the machine remotely.

Digital Display Of Air Pressure

Controlling the air pressure has never been easier with the digital air pressure display and the handy air regulator located right beside the machine.

Dual Air Pressure

Engraving and cutting require different air pressures. For cutting, strong air enhances quality and efficiency, while engraving needs lower pressure for precision. Additionally, a weak air flow keeps the lens clean. The dual air system on Redline can be easily switched via software to meet these demands without a hiccup.

Ultra Safe:

Prioritizing Your Health & Safety

Prioritizing Your Health & Safety

The importance of safety when using the laser machine cannot be overstated.

AEON cares about your heath and safety all the time.

We have taken numerous steps to ensure that.

AEON cares about your heath and safety all the time.

We have taken numerous steps to ensure that.

Class I Laser

Product

Product

The Redline series features a fully enclosed cabinet with fail safe interlocks on all doors to prevent electrical leaks and potential risks. Its radiation levels are much lower than those of a Class I laser product.

TUV

Certified

Certified

We take the pride to meet the most strict testing standard of the world known TUV Rheinland. Their comprehensive safety testing and invaluable professional safety knowledge have been priceless to us.

Get a Quote

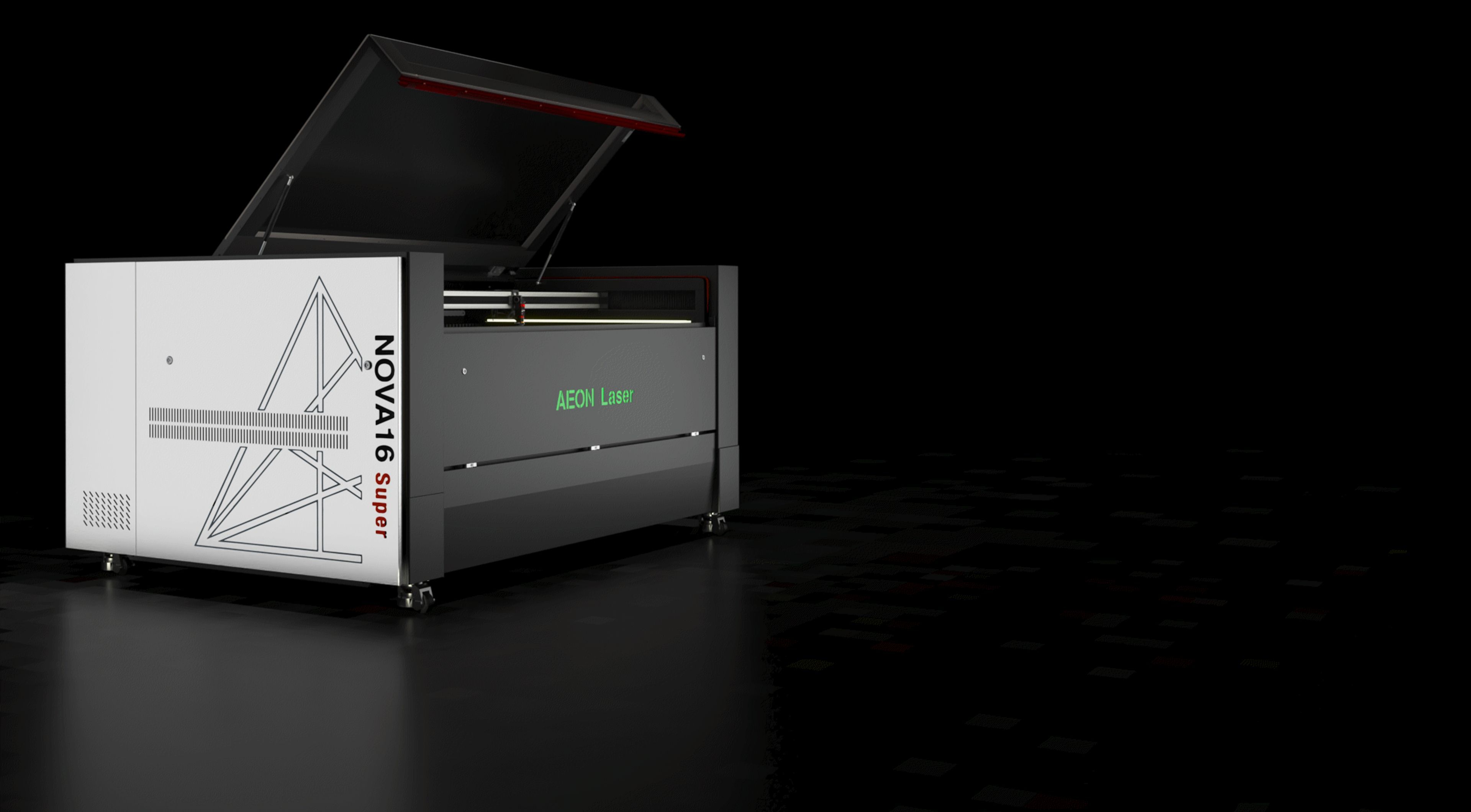

State Of Art Design

Unmatched Brilliance In Every Detail

Unmatched Brilliance In Every Detail

AEON is renowned for its stylish, sleek and elegant appearance.

The new Redline series preserves our cherished heritage while introducing dazzling innovations

The new Redline series preserves our cherished heritage while introducing dazzling innovations

Compact All In One Solution

If space is of concern, you'll be pleased to know that Aeon is the first in the laser industry to offer an all-in-one solution comprised of an integrated water cooling system, exhaust fan and air assist pump so that no extra space is needed for ancillary components, minimizing the footprint of the machine and making your workspace neater and more organized.

LED Status Light

The Aeon Laser logo on the front access door panel is now backlit and doubles as a functional Status Light, illuminating white when in standby, red when an error is encountered, and green while in operation, adding both form and function to an already stunning design.

Every Detail Is Crafted For Your Comfort

Peer into the working area, you'll find no unsightly screws, exposed rails or excess gaps. We separated the mechanics from the electric components. Sealed the whole cabinet with soft silicon strip, even shield the ball screw with protective brush, add filters for every cooling fans, everything is meticulously arranged to make you comfortable...

Own it and start your creative journey...

Get a Quote