Here is a new, well-researched, and structurally consistent version of the webpage text for CO₂ laser applications on metal, adapted to match your materials section format. This reflects the real, limited but valid uses of CO₂ lasers in metal applications — such as marking coated surfaces or anodized aluminum, and engraving painted or treated metals.

CO₂ Laser Applications for Metal (Surface Marking Only)

Non-Contact Laser Engraving & Coating Removal on Select Metal Surfaces

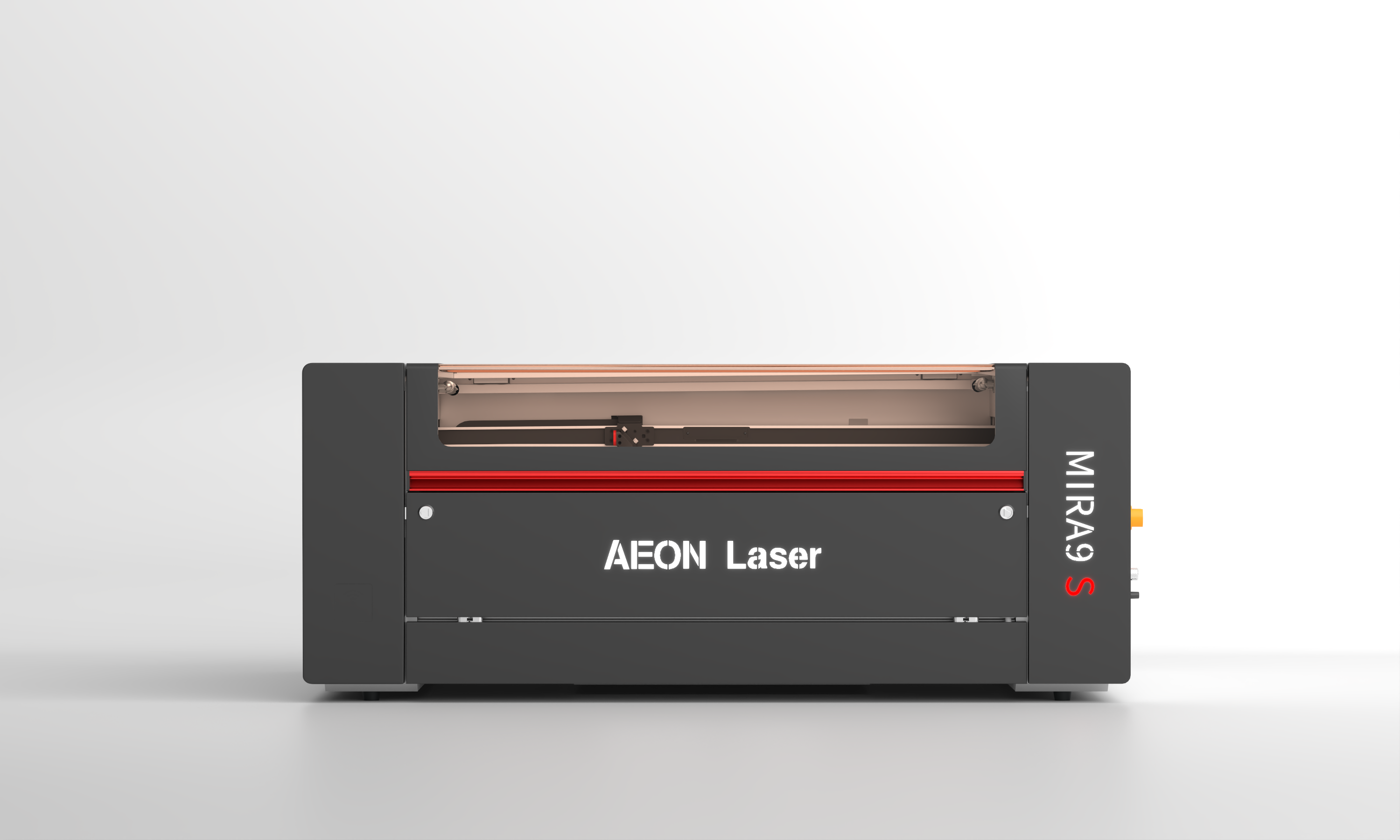

While CO₂ lasers are not powerful enough to cut or deep-engrave bare metals, they are highly effective for marking coated, anodized, or painted metal surfaces. AEON’s CO₂ laser systems offer clean, detailed engraving on treated metals — without physical contact, tool wear, or the need for additional consumables.

This makes them ideal for branding, serial number marking, signage, and decorative applications on coated substrates, especially in industries like electronics, awards, gifts, and light manufacturing.

✅ Why Use CO₂ Lasers for Metal Marking?

· Perfect for Coated & Anodized Surfaces

Engrave logos or serial numbers on anodized aluminum, powder-coated steel, or painted brass.

· No Physical Contact = No Tool Wear

Laser marking is clean, maintenance-free, and ideal for detailed artwork or serial marking.

· High-Speed Graphic Processing

Process barcodes, QR codes, schematics, or artwork directly onto coated metal surfaces.

· Efficient for Identification & Branding

Add part numbers, logos, or data matrix codes for traceability or customization.

· Compatible with Fixtures & Rotary Devices

Mark cylindrical metal items such as flasks or metal pens using AEON’s rotary accessories.

Compatible Metal Materials for Surface Marking

Material Type | Use Case | CO₂ Laser Capability |

Anodized Aluminum | Nameplates, ID tags, industrial panels | High-contrast surface engraving |

Painted or Powder-Coated Metal | Enclosures, control panels, flasks | Coating removal reveals base material |

Stainless Steel (with coating spray) | Tools, labels, plates | Indirect black marking with laser spray |

Brass (painted/coated only) | Decorative plates, tags | Coating removal, contrast engraving |

Aluminum Composite Panels (ACP) | Signage, architectural panels | Surface engraving or layer stripping |

⚠️ Note: Bare metals (e.g., raw stainless steel, aluminum, copper) cannot be directly engraved or cut by CO₂ lasers. For these, fiber lasers are required. However, coated surfaces can be reliably marked with excellent results using CO₂ lasers.

Business & Creative Use Cases

· ✅ Industrial marking — serial numbers, barcodes, asset tracking

· ✅ Custom branding — logos and artwork on flasks, pens, or tags

· ✅ Promotional products — engraved giveaways on anodized aluminum

· ✅ Architectural signage — layered ACP panels and nameplates

· ✅ Award engraving — coated trophies, plaques, or metal badges

· ✅ Workshop tools — identification marks or labels using spray

· ✅ Personalized metal gifts — engraved power banks, wallets, card holders

Pro Tips

· Use low-to-medium power and high-speed settings for surface engraving on anodized aluminum or powder-coated metals.

· For stainless steel, apply laser marking spray (e.g., CerMark or Thermark) to enable black marking — remove residue afterward.

· Test coating thickness beforehand — some cheap powder coats vaporize inconsistently and may require multiple passes.