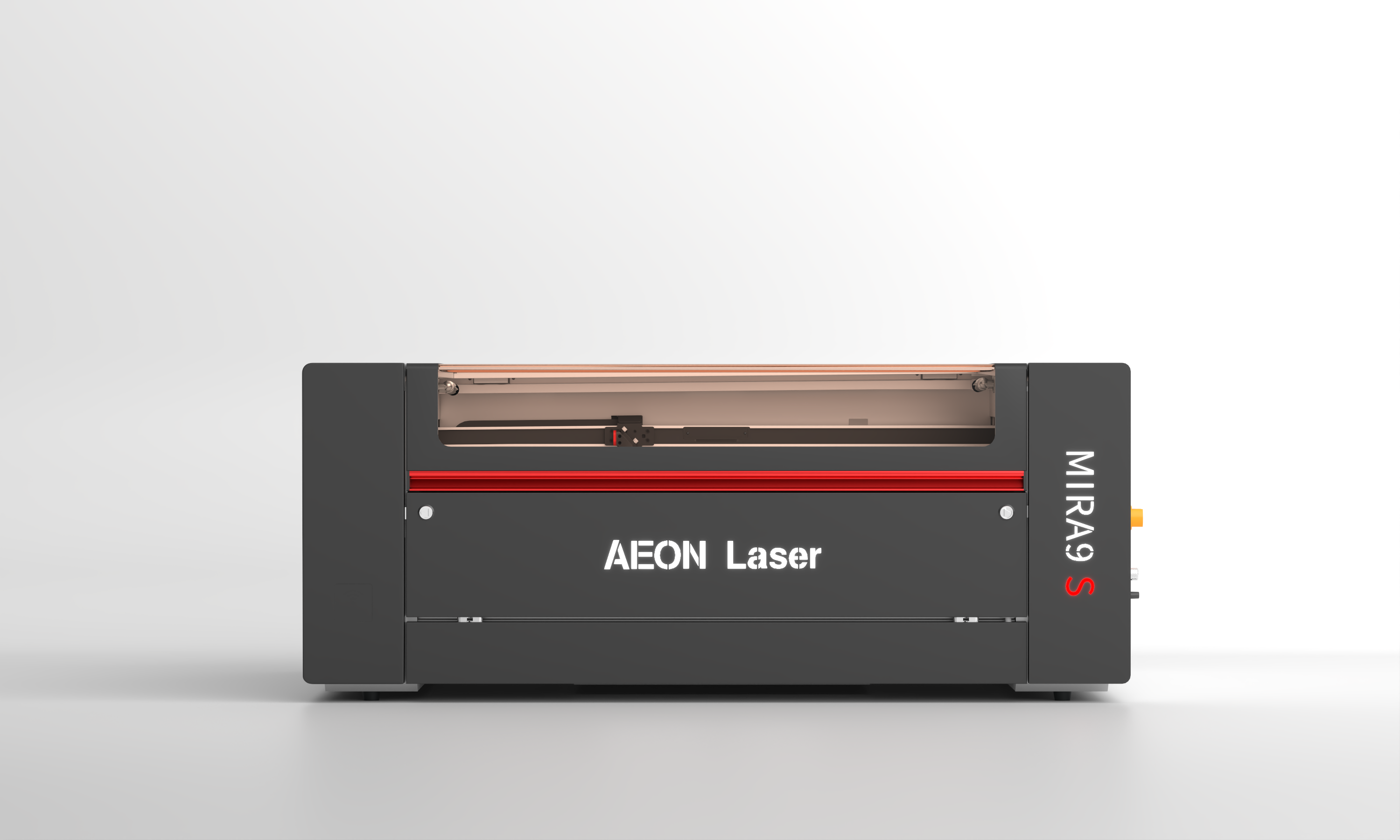

⚙️ CO₂ Laser Applications for Elastomers (Non-Foam)

Precision Cutting and Marking of Rubber and Flexible Polymer Sheets with AEON Laser

CO₂ laser systems are highly effective for processing a wide range of elastomers—flexible, rubber-like materials commonly used in industrial, automotive, and creative applications. CO₂ lasers enable precise, contactless cutting of elastomer sheets with clean edges, complex geometries, and high repeatability. While deep engraving is generally limited, surface marking is possible on select materials.

✅ Why Use CO₂ Lasers for Elastomers?

· Clean, Accurate Cutting

Cuts flexible materials without deformation, fraying, or tool wear—ideal for gasket manufacturing, seals, and custom components.

· Non-Contact Processing

Eliminates mechanical stress, reducing the risk of tearing or material distortion, especially on intricate designs.

· Supports Complex Geometries

Ideal for cutting fine details like holes, slots, curves, and complex gasket outlines.

· Fast Prototyping & Low-Volume Production

No physical dies are needed, offering flexible production for custom orders or fast design iteration.

· Surface Marking on Select Rubbers

Shallow marking is achievable for labeling, part identification, or branding, though contrast depends on the material.

� Elastomers Compatible with CO₂ Lasers (Foams Excluded)

Material | Suitability | Application Notes |

Natural Rubber (NR) | ✔️ Cut, mark | Widely used for seals and gaskets; cuts well with typical edge darkening; noticeable odor. |

Neoprene (CR) | ✔️ Cut, mark | Popular in marine, sports, and gasket industries; cuts clean with a moderate odor. |

EPDM (Ethylene Propylene Diene) | ✔️ Cut, mark | UV- and weather-resistant rubber; common in automotive and roofing; minor charring on edges. |

Nitrile Rubber (NBR) | ✔️ Cut, mark | Oil-resistant rubber for industrial seals; cuts cleanly with darker edges. |

SBR (Styrene-Butadiene Rubber) | ✔️ Cut | Economical rubber used in mats, shoe soles, and flooring; cuts well, but edges darken. |

Silicone Rubber (solid sheets) | ✔️ Cut only | Cuts exceptionally clean; almost no burning; surface marking is shallow with limited contrast. |

Viton® / FKM (Fluoroelastomers) | ❌ Not suitable | Hazardous: Releases hydrogen fluoride gas when lasered—strictly prohibited. |

PVC-Based Rubber Composites | ❌ Not suitable | Toxic: Emits chlorine gas; absolutely unsuitable for laser processing. |

⚠️ Important Material Safety Notes:

· Strictly avoid:

· PVC-containing rubbers → Chlorine gas risk.

· Viton® / FKM → Emits highly toxic hydrogen fluoride gas.

· Always verify the exact composition of the elastomer before processing.

· Adequate fume extraction is mandatory even for safe rubber types, as natural rubber compounds produce significant smoke and odor.

� Common Business Applications

Industry | Application Examples |

Industrial | Custom gaskets, washers, vibration dampeners, seals for machinery |

Automotive | Window seals, weatherstripping, under-hood gaskets, rubber spacers |

Manufacturing | Conveyor belt guides, impact pads, tool grips |

Creative & DIY | Rubber stamps (for natural rubber), custom accessories, art panels |

Footwear | Outsoles, midsoles, custom patterned rubber inserts |

Crafts & Design | Custom-patterned mats, home decor elements, and creative signage with rubber textures |

Pro Tips for Laser Processing of Elastomers

· Air Assist is Crucial: Reduces smoke buildup and improves edge quality.

· High Speed, Moderate Power: Helps reduce edge burning, especially on natural and synthetic rubbers.

· Odor Management: Rubber cutting produces strong odors—use an efficient fume extraction system.

· Test for Marking: Surface marking quality varies—silicone marks lightly, neoprene and EPDM mark better with dark contrast.

· Edge Quality: Expect some natural edge darkening, especially with natural rubber and NBR; this is normal and functional for most industrial uses.